Need Something More Customised?

Let SPACERACK find the best solution for you

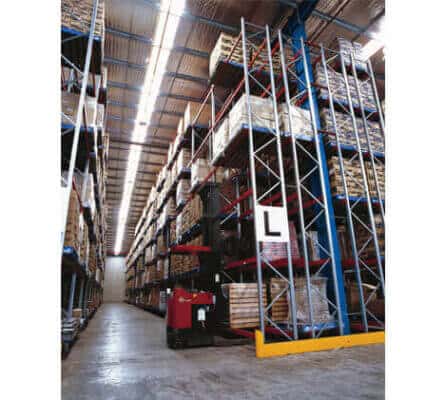

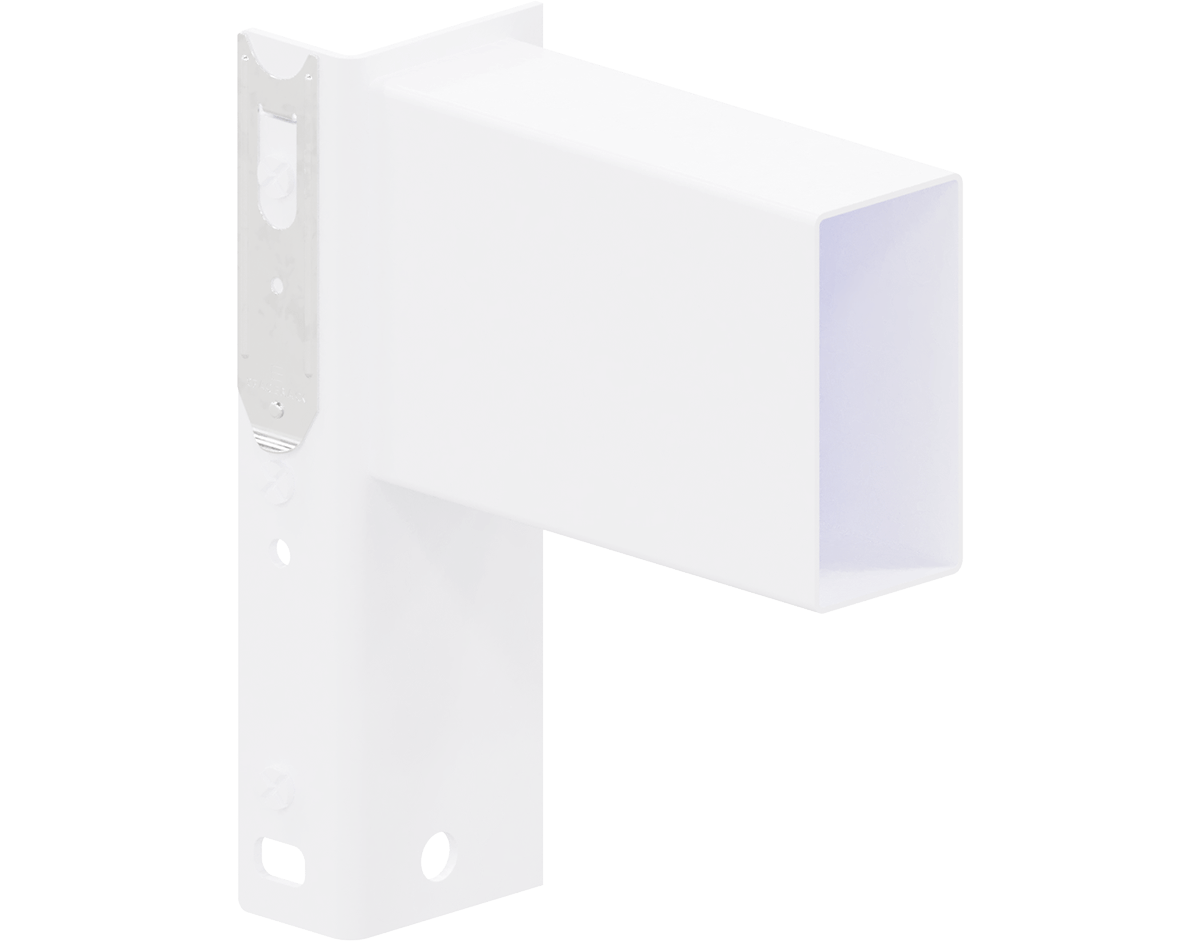

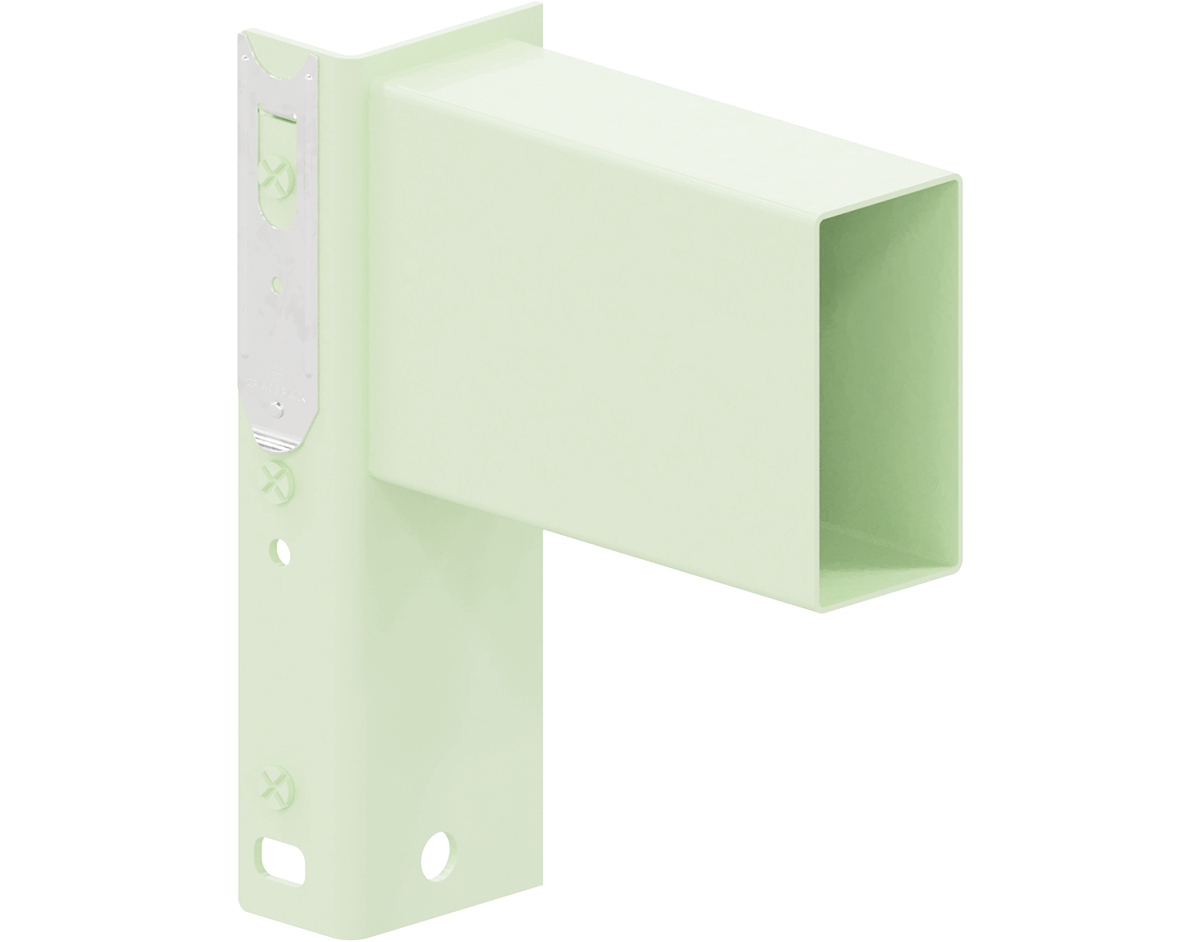

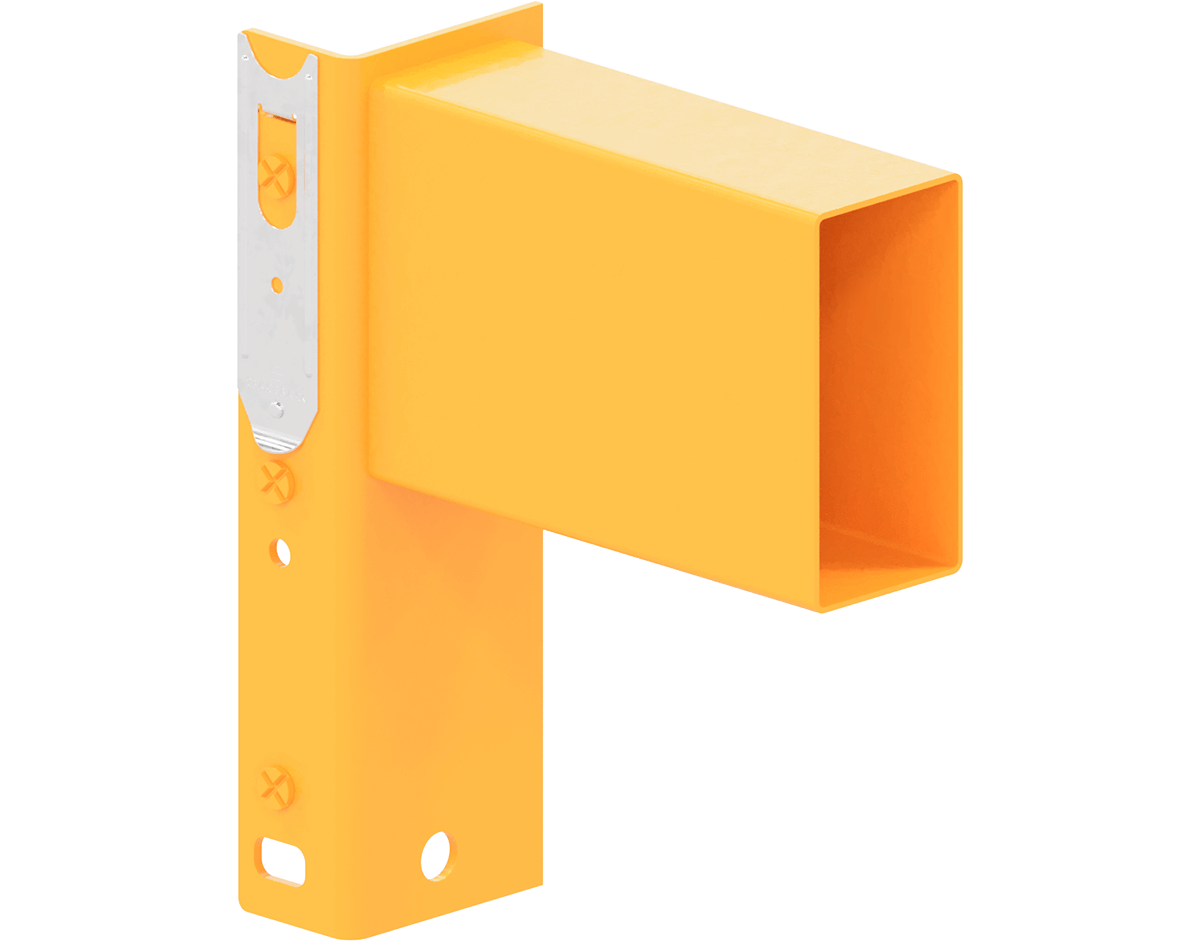

SPACERACK can design storage solutions to meet your space requirements, including pallet racking types (e.g. Selective, Narrow Aisles, Drive-In) to suit your warehouse, Raised Storage Areas to add space to your warehouse, Cantilever Racking (light, medium, heavy or structural) to suit your load requirements, and other racking and industrial storage related products.

SPACERACK’s in-house designers grants us the flexibility to design and build the perfect storage solution tailored to your unique storage requirements. Call us on 1800 814 134 or fill out this form and we will be in contact with you ASAP.